High Precision, High Accuracy: The Key to Success

In today’s fast-paced and competitive world, the demand for high precision and high accuracy has never been greater. Whether it’s in manufacturing, engineering, healthcare, or any other industry, the ability to deliver precise and accurate results is crucial for success.

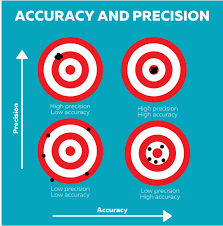

Precision refers to the consistency of measurements or observations when repeated under the same conditions. A high level of precision means that the results are close to each other and have minimal variation. This is essential for ensuring reliability and repeatability in processes.

Accuracy, on the other hand, relates to how close a measurement is to the true value or target. Achieving high accuracy means that the results are not only consistent but also aligned with the desired outcome. Accuracy is vital for making informed decisions and achieving desired goals.

When precision and accuracy work hand in hand, they form a powerful combination that can drive innovation, efficiency, and excellence. High precision ensures that outcomes are reliable and consistent, while high accuracy guarantees that these outcomes are aligned with expectations.

Businesses that prioritise high precision and high accuracy are better equipped to deliver superior products and services to their customers. From intricate manufacturing processes to intricate medical procedures, precision and accuracy play a critical role in enhancing quality and performance.

Furthermore, embracing a culture of continuous improvement in precision and accuracy can lead to cost savings, reduced waste, increased productivity, and ultimately higher customer satisfaction. By investing in technologies, training programmes, and quality control measures that promote precision and accuracy, organisations can stay ahead of the curve.

In conclusion, high precision and high accuracy are not just buzzwords; they are fundamental principles that underpin success in today’s competitive landscape. By striving for excellence in every aspect of operations and decision-making, businesses can unlock new opportunities for growth and establish themselves as leaders in their respective fields.

7 Essential Tips for Achieving High Precision and Accuracy in Measurements

- Ensure proper calibration of equipment regularly.

- Use the appropriate measuring tools for the specific task.

- Follow standard operating procedures carefully.

- Minimize environmental factors that could affect measurements.

- Train personnel on accurate measurement techniques.

- Implement quality control checks throughout the process.

- Document all measurements and results accurately.

Ensure proper calibration of equipment regularly.

To maintain high precision and accuracy in measurements, it is crucial to ensure the proper calibration of equipment regularly. By calibrating instruments and tools at scheduled intervals, businesses can verify the accuracy of readings and adjust any deviations to maintain reliability. Regular calibration not only enhances the consistency of results but also instils confidence in the data obtained, leading to informed decision-making and improved overall quality in operations.

Use the appropriate measuring tools for the specific task.

When aiming for high precision and accuracy in any task, it is crucial to use the appropriate measuring tools tailored to the specific requirements of the job at hand. Selecting the right tools not only ensures that measurements are taken correctly but also enhances the reliability and consistency of the results obtained. By matching the measuring instruments to the unique characteristics of the task, individuals and organisations can effectively improve their processes, make informed decisions, and achieve desired outcomes with confidence and precision.

Follow standard operating procedures carefully.

Following standard operating procedures carefully is a crucial tip for achieving high precision and high accuracy in any task or process. SOPs provide a structured framework that outlines the necessary steps to be taken, ensuring consistency and adherence to best practices. By meticulously following SOPs, individuals can eliminate errors, reduce variability, and maintain the desired level of precision and accuracy in their work. This disciplined approach not only enhances the quality of outcomes but also instils confidence in stakeholders regarding the reliability and integrity of the results obtained.

Minimize environmental factors that could affect measurements.

To achieve high precision and high accuracy in measurements, it is essential to minimise environmental factors that could introduce errors or inconsistencies. Controlling variables such as temperature, humidity, vibration, and electromagnetic interference can help maintain the stability of measurement conditions. By creating a controlled environment free from external influences, we can ensure that our measurements are reliable, consistent, and aligned with the true values we aim to achieve. This attention to detail in managing environmental factors is key to producing accurate results and enhancing the overall quality of our work.

Train personnel on accurate measurement techniques.

To achieve high precision and high accuracy in any setting, it is essential to train personnel on accurate measurement techniques. By providing comprehensive training on proper measurement procedures, calibration processes, and error minimisation strategies, organisations can empower their workforce to consistently deliver precise and accurate results. Equipping personnel with the knowledge and skills to perform measurements correctly not only enhances the quality of output but also instils a culture of excellence and attention to detail within the team. Investing in training programmes for accurate measurement techniques is a strategic move towards ensuring reliability, consistency, and success in achieving desired outcomes.

Implement quality control checks throughout the process.

To achieve high precision and high accuracy, it is essential to implement quality control checks throughout the process. By incorporating checkpoints at various stages of production or execution, businesses can monitor and verify the consistency and correctness of their operations. These quality control measures help identify any deviations from the desired standards early on, allowing for timely adjustments and corrections to maintain precision and accuracy. Through vigilant monitoring and adherence to quality control protocols, organisations can ensure that their outputs meet the required specifications, leading to enhanced reliability, customer satisfaction, and overall success.

Document all measurements and results accurately.

To uphold the principles of high precision and high accuracy, it is essential to meticulously document all measurements and results with utmost accuracy. By maintaining detailed records of each step in the measurement process, including the instruments used, environmental conditions, and any potential sources of error, you can ensure the reliability and reproducibility of your data. Accurate documentation not only serves as a reference for future analysis but also enables transparency and accountability in your work, fostering a culture of precision and excellence.