The Importance of High Precision and High Accuracy

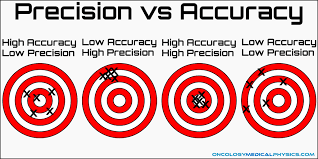

When it comes to measurements and calculations, two key terms often come into play: precision and accuracy. While they are related concepts, they have distinct meanings that are crucial in various fields such as science, engineering, manufacturing, and technology.

Precision

Precision refers to the level of consistency or repeatability in a set of measurements. A high precision measurement means that repeated measurements under the same conditions yield similar results. In other words, precision indicates how close multiple measurements are to each other.

Accuracy

Accuracy, on the other hand, describes how close a measured value is to the true or accepted value. It reflects the degree of correctness in a measurement. An accurate measurement means that it is close to the true value, regardless of whether it is precise or not.

Importance in Various Fields

In scientific research, high precision ensures that experimental results are reliable and reproducible. Researchers can trust the data obtained from precise measurements when drawing conclusions or making decisions based on their findings.

In engineering and manufacturing processes, both high precision and high accuracy are essential for producing quality products. Precise measurements help ensure components fit together perfectly, while accurate measurements guarantee that products meet design specifications.

In fields such as medicine and technology, accuracy is paramount when dealing with sensitive data or critical operations. For example, medical devices must provide accurate readings for diagnosis and treatment purposes to ensure patient safety and well-being.

Conclusion

High precision and high accuracy play vital roles in various aspects of our lives, from scientific research to everyday technologies. Understanding the differences between these two concepts is key to obtaining reliable results, making informed decisions, and achieving excellence in our endeavours.

Understanding High Precision and High Accuracy: Key FAQs Answered

- What is the difference between high precision and high accuracy?

- Why are high precision and high accuracy important in scientific research?

- How do high precision and high accuracy impact engineering and manufacturing processes?

- What are the consequences of low precision in measurements?

- Can a measurement be precise but not accurate, or vice versa?

- How can one improve both precision and accuracy in measurements?

- Are there tools or technologies that help achieve high precision and high accuracy?

What is the difference between high precision and high accuracy?

The distinction between high precision and high accuracy lies in their respective definitions. High precision refers to the consistency and repeatability of measurements, indicating how closely repeated measurements match each other. On the other hand, high accuracy pertains to the closeness of a measured value to the true or accepted value, regardless of whether the measurements are consistent or not. In essence, while high precision emphasises the reliability and consistency of measurements, high accuracy focuses on how close those measurements are to the actual value being measured. Understanding this difference is crucial in various fields where precise and accurate data are essential for achieving reliable results and making informed decisions.

Why are high precision and high accuracy important in scientific research?

In scientific research, high precision and high accuracy are crucial for ensuring the reliability and validity of experimental results. High precision allows researchers to obtain consistent and reproducible measurements, reducing the likelihood of random errors and increasing the confidence in the data collected. On the other hand, high accuracy ensures that the measured values are close to the true or accepted values, enabling researchers to draw accurate conclusions and make informed decisions based on their findings. Without high precision and high accuracy in scientific research, there is a risk of obtaining misleading results that could lead to incorrect interpretations and conclusions, ultimately impacting the advancement of knowledge in various fields of study.

How do high precision and high accuracy impact engineering and manufacturing processes?

In engineering and manufacturing processes, the impact of high precision and high accuracy is profound. High precision ensures that components are consistently manufactured with tight tolerances, leading to better quality control and product performance. Precision plays a crucial role in ensuring that parts fit together seamlessly, reducing errors and rework in assembly processes. On the other hand, high accuracy ensures that final products meet design specifications and perform as intended. Accurate measurements help prevent defects, improve efficiency, and enhance overall product reliability. Together, high precision and high accuracy are essential in engineering and manufacturing to achieve excellence in production outcomes and customer satisfaction.

What are the consequences of low precision in measurements?

Low precision in measurements can have significant consequences across various fields. When measurements lack consistency and repeatability, it becomes challenging to rely on the data obtained for making informed decisions or drawing accurate conclusions. In scientific research, low precision can lead to unreliable results, hindering the progress of experiments and potentially leading to incorrect findings. In engineering and manufacturing, low precision can result in products that do not meet quality standards or specifications, leading to inefficiencies and potential safety risks. Furthermore, in fields such as healthcare and technology, inaccurate measurements due to low precision can have serious implications for patient care or system performance. Therefore, ensuring high precision in measurements is essential for maintaining the integrity and reliability of data in order to achieve successful outcomes.

Can a measurement be precise but not accurate, or vice versa?

In the realm of measurements, it is indeed possible for a measurement to be precise but not accurate, or vice versa. Precision refers to the consistency and repeatability of measurements, indicating how close multiple measurements are to each other. On the other hand, accuracy relates to how close a measured value is to the true or accepted value. Therefore, a measurement can be precise if repeated measurements yield similar results, even if they are not close to the true value. Similarly, a measurement can be accurate if it is close to the true value, regardless of whether it is consistent with other measurements. Understanding this distinction is crucial in various fields where both precision and accuracy are essential for obtaining reliable and meaningful data.

How can one improve both precision and accuracy in measurements?

To improve both precision and accuracy in measurements, several key strategies can be implemented. Firstly, using calibrated and high-quality measuring instruments is essential to ensure accurate readings. Regular calibration and maintenance of equipment help maintain accuracy over time. Additionally, conducting multiple trials and averaging the results can enhance precision by reducing random errors. Proper training for personnel involved in measurements is crucial to minimise human errors and ensure consistency. Implementing standard operating procedures and quality control measures can also contribute to improving both precision and accuracy in measurements. By following these practices diligently, one can achieve more reliable and trustworthy measurement outcomes.

Are there tools or technologies that help achieve high precision and high accuracy?

In the pursuit of achieving high precision and high accuracy in measurements and calculations, various tools and technologies play a crucial role. Precision measuring instruments such as micrometers, calipers, laser interferometers, and coordinate measuring machines are commonly used to ensure consistent and reliable results. Advanced technologies like computer-aided design (CAD), computer numerical control (CNC) machines, and robotic systems also contribute to enhancing precision and accuracy in manufacturing processes. These tools enable professionals across different industries to attain the desired level of precision and accuracy required for their specific applications, ultimately leading to improved quality, efficiency, and performance.