Accuracy and Precision: Understanding the Difference

In many fields, accuracy and precision are terms that are often used interchangeably. However, they have distinct meanings and play crucial roles in various domains, including science, engineering, and even everyday life. Understanding the difference between accuracy and precision is essential for ensuring reliable results and making informed decisions.

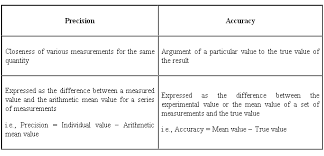

Accuracy refers to how close a measured value is to the true or target value. It is an indication of how well a measurement represents the actual quantity being measured. In other words, accuracy tells us whether our measurements are correct or not. For example, if a thermometer consistently reads 1°C lower than the actual temperature, it is considered accurate as long as it consistently shows this offset.

On the other hand, precision refers to the level of consistency or reproducibility in repeated measurements. It reflects how closely individual measurements agree with each other. Precise measurements have very little variation between them, indicating a high degree of reliability and consistency. For instance, if a scale consistently measures an object’s weight as 10 grams when it actually weighs 9 grams, it is precise but not accurate.

To illustrate further, imagine a target board with multiple arrows shot at it. Accuracy would mean that all arrows hit the bullseye or are clustered around the same spot (even if not on target). Precision would mean that all arrows hit closely together but not necessarily near the bullseye.

In scientific experiments or engineering projects, both accuracy and precision are crucial considerations. Achieving high levels of both can be challenging but extremely important for obtaining reliable results. A measurement can be accurate but not precise (consistently off-target), precise but not accurate (consistently off-target but consistent), neither accurate nor precise (inconsistent readings), or both accurate and precise (consistent and on-target).

It’s important to note that accuracy does not guarantee precision nor vice versa. Obtaining accurate results may require calibrating instruments, minimizing systematic errors, and accounting for uncertainties. Enhancing precision often involves reducing random errors and increasing the number of measurements taken.

In real-life scenarios, accuracy and precision are also relevant. For example, in manufacturing processes, precise measurements are needed to ensure consistent product quality. In medical diagnostics, accurate test results are essential for correct diagnoses. In navigation systems, accuracy is crucial for determining precise locations.

Understanding the distinction between accuracy and precision empowers individuals to critically evaluate data and measurements. It helps in identifying sources of error and making informed decisions based on reliable information. By striving for both accuracy and precision in our work and everyday lives, we can achieve greater levels of confidence, reliability, and success.

Understanding the Distinction: Accuracy and Precision in Measurements

- Accuracy reflects how close a measurement is to its true value, while precision reflects how consistently the same result can be repeated.

- Accurate results help identify and fix problems, while precise results provide evidence of consistency and quality control.

- Accurate measurements are more reliable than precise measurements when making decisions or forming conclusions.

- Precision allows for repeatable experiments, which helps detect trends and patterns that would otherwise be difficult to observe with inaccurate data points.

- Knowing the difference between accuracy and precision helps ensure that data-driven decisions are based on valid information rather than guesswork or assumptions.

- Precision instruments are able to measure very small changes in data points, whereas accurate instruments may miss these subtle variations without proper calibration and maintenance procedures in place.

- Accuracy is important for providing meaningful results, while precision is important for ensuring consistent performance over time from a given device or system of measurement equipment.

- Accuracy and precision are both key components of quality assurance processes, helping to ensure that products meet customer requirements and industry standards

Challenges and Consequences of Accuracy and Precision Differences in Quality Control

- Accuracy and precision can be difficult to measure, making it difficult to ensure quality control.

- Lack of accuracy and precision can lead to data misinterpretation or incorrect decisions being made.

- Poor accuracy and precision can result in costly mistakes, such as inaccurate inventory counts or incorrect measurements in manufacturing processes.

- If accuracy and precision are not maintained, the results of any experiment or process may be unreliable and invalidate the results obtained from it.

Accuracy reflects how close a measurement is to its true value, while precision reflects how consistently the same result can be repeated.

The Pro of Accuracy and Precision: A Reliable Measure

When it comes to measurements, accuracy and precision are two important factors that contribute to the reliability of results. While accuracy reflects how close a measurement is to its true value, precision focuses on the consistency of repeated results. Understanding this distinction is key to obtaining trustworthy data in various fields.

Accuracy ensures that our measurements are as close as possible to the true value we are trying to determine. It allows us to gauge how well our instruments and techniques perform in capturing the intended quantity. For instance, in scientific experiments, accurate measurements are crucial for drawing valid conclusions and making informed decisions based on reliable data.

On the other hand, precision assesses the consistency and reproducibility of our measurements. It tells us how closely repeated measurements agree with each other. A high level of precision indicates that our results are consistent and reliable, even if they may not be on target or accurate. This aspect is particularly significant when it comes to quality control processes or when conducting experiments that require precise replication.

The advantage of understanding the difference between accuracy and precision lies in obtaining a comprehensive evaluation of our measurements. By considering both factors, we can assess the reliability of our data more effectively.

For example, imagine a scenario where we need to measure the length of an object using a ruler. If our ruler is accurately calibrated but lacks precision, repeated measurements may yield slightly different results each time. In this case, while individual readings may not be consistent with each other (low precision), they might still be close to the true value (high accuracy).

Conversely, if our ruler consistently provides identical readings but is not accurately calibrated (low accuracy), all measurements will have little deviation from one another (high precision). However, they will consistently deviate from the actual length being measured.

By recognizing this distinction between accuracy and precision, we can identify areas for improvement in our measurement processes. We can calibrate instruments to enhance accuracy, reducing systematic errors and ensuring measurements are closer to the true value. To boost precision, we can focus on reducing random errors and increasing the number of measurements taken.

In summary, accuracy and precision are both essential for reliable measurements. Accuracy allows us to estimate how close our measurements are to the true value, while precision tells us how consistently we can reproduce the same result. By striving for both accuracy and precision, we ensure that our data is trustworthy, enabling us to make informed decisions and draw valid conclusions in various fields of study.

Accurate results help identify and fix problems, while precise results provide evidence of consistency and quality control.

The Pro of Accuracy and Precision: Identifying Problems and Ensuring Quality

In the realm of measurements and data analysis, accuracy and precision play vital roles in differentiating between reliable information and potential issues. The distinction between accurate and precise results offers distinct advantages, contributing to problem-solving and maintaining quality control.

Accurate results are crucial for identifying problems. When measurements are accurate, they closely align with the true or target value being measured. This accuracy enables us to pinpoint discrepancies, deviations, or errors within a system or process. By comparing accurate measurements to expected values or standards, we can quickly identify areas that require attention or improvement.

For example, in manufacturing, accurate measurements help identify variations in product dimensions. If a product consistently falls outside the acceptable range of accuracy, it indicates a problem in the production line that needs to be addressed. By identifying these issues promptly, corrective measures can be taken to improve the overall quality of the products.

On the other hand, precise results provide evidence of consistency and quality control. Precise measurements exhibit minimal variation between repeated measurements of the same quantity. This precision demonstrates that a process or system is producing consistent outcomes.

In industries where quality control is paramount, precision plays a significant role in ensuring products meet specific standards. For instance, in pharmaceutical manufacturing, precise measurements are essential for maintaining uniformity in medication dosages. Precise results provide evidence that the manufacturing process is tightly controlled and consistently produces reliable products.

Moreover, precision aids in detecting even minor changes within a system. By monitoring precision over time or across different batches, any deviations from expected levels can be identified early on. This allows for proactive measures to maintain quality control before it escalates into larger issues.

Accurate results help us identify problems by highlighting discrepancies from expected values or targets. They act as valuable indicators that prompt investigation and corrective actions when needed. On the other hand, precise results offer evidence of consistency over time and demonstrate effective quality control measures.

By understanding and leveraging the benefits of both accuracy and precision, industries can enhance their problem-solving capabilities while ensuring consistent quality in their processes and products. The combination of accurate and precise measurements empowers organizations to make informed decisions, implement improvements, and maintain high standards of excellence.

Accurate measurements are more reliable than precise measurements when making decisions or forming conclusions.

Accurate Measurements: The Key to Reliable Decisions

When it comes to making decisions or forming conclusions, accurate measurements hold a significant advantage over precise measurements. While both accuracy and precision are important, accuracy takes precedence in ensuring reliability and confidence in the information we rely on.

Accurate measurements provide a true representation of the quantity being measured, allowing us to trust the data we have collected. They reflect how close our measurements are to the actual value or target value we are trying to determine. By obtaining accurate measurements, we can have greater confidence in the validity of our findings.

On the other hand, precise measurements focus on consistency and reproducibility. While precision is valuable in many contexts, it does not necessarily guarantee accuracy. Precise measurements may exhibit very little variation between repeated observations, but they might still be consistently off-target or incorrect.

When making decisions or drawing conclusions based on data, accuracy becomes paramount. It ensures that our findings align with reality and that our actions are based on reliable information. For example, in scientific research, accurate measurements are crucial for drawing valid conclusions and establishing cause-and-effect relationships.

Consider a medical diagnosis where precise but inaccurate test results could lead to misdiagnosis and improper treatment. In this scenario, accurate measurements become vital for accurate diagnoses and appropriate medical interventions.

Accuracy also plays a critical role in fields such as engineering and manufacturing. Precise but inaccurate measurements could result in products that do not meet specifications or perform as intended. Accurate measurements ensure that products are manufactured within acceptable tolerances and meet quality standards.

While precision has its merits in certain applications (such as when consistency is essential), it is accuracy that provides us with reliable insights for decision-making purposes. Accurate data allows us to make informed choices with confidence, leading to better outcomes and minimizing potential risks.

To achieve accuracy in measurement, it is important to consider factors such as calibration, minimizing systematic errors, accounting for uncertainties, and using appropriate measurement techniques. By prioritizing accuracy, we can ensure the reliability of our data and make well-informed decisions that have a positive impact.

In conclusion, accurate measurements are more reliable than precise measurements when it comes to making decisions or forming conclusions. Accuracy ensures that our data reflects reality and provides a solid foundation for informed choices. By valuing accuracy in our measurements, we can enhance the reliability of our findings and ultimately achieve better outcomes in various domains of life.

Precision allows for repeatable experiments, which helps detect trends and patterns that would otherwise be difficult to observe with inaccurate data points.

The Pro of Precision: Unveiling Trends and Patterns

In the realm of scientific research and experimentation, precision plays a pivotal role in unraveling hidden trends and patterns. By enabling repeatable experiments and generating consistent data points, precision provides scientists with a powerful tool to detect subtle relationships that would otherwise remain obscured by inaccuracies.

When conducting experiments, it is crucial to minimize random errors that can introduce variability into the data. By employing precise measurement techniques and reducing uncertainties, researchers can obtain highly consistent results. This consistency allows for accurate comparisons between different sets of data, leading to a clearer understanding of the underlying phenomena.

One significant advantage of precision is its ability to uncover trends over time or across various conditions. When measurements are precise and reproducible, scientists can confidently identify even the slightest changes or variations in their data sets. These subtle shifts may hold valuable insights into cause-and-effect relationships or provide evidence for emerging patterns.

Imagine a study investigating the impact of temperature on plant growth. With imprecise measurements, it would be challenging to discern any meaningful correlation between temperature fluctuations and plant development. However, by employing precise measurement techniques and ensuring consistency in data collection, researchers can detect nuanced growth patterns that may have gone unnoticed otherwise.

Precision also plays a crucial role in fields such as statistics and data analysis. Accurate but imprecise measurements may lead to misleading conclusions or inaccurate predictions. In contrast, precise measurements provide reliable data points that allow statisticians to identify significant trends, correlations, or anomalies with confidence.

Moreover, precision facilitates the identification of outliers or anomalies within a dataset. These outliers may hold critical information about unusual occurrences or unexpected behaviors. By carefully examining these deviations from the norm, scientists can gain valuable insights into unique phenomena or uncover previously unknown factors influencing their experiments.

In summary, precision fosters repeatability in experiments by generating consistent and reliable data points. This repeatability enables scientists to detect trends and patterns that would otherwise remain hidden amidst inaccuracies. By minimizing random errors and maximizing precision, researchers can confidently analyze their data, make accurate comparisons, and unravel the intricate relationships governing the natural world.

The pro of precision lies in its ability to provide a clearer picture of the underlying mechanisms at play. It empowers scientists to make informed decisions, draw accurate conclusions, and contribute to the advancement of knowledge in their respective fields.

Knowing the difference between accuracy and precision helps ensure that data-driven decisions are based on valid information rather than guesswork or assumptions.

Knowing the Difference: Accuracy and Precision in Data-Driven Decisions

In today’s data-driven world, making informed decisions is paramount. Whether it’s in business, research, or personal matters, having access to accurate and precise information is crucial. Understanding the difference between accuracy and precision plays a significant role in ensuring that decisions are based on valid information rather than guesswork or assumptions.

Accuracy, as we know, refers to how close a measured value is to the true or target value. When it comes to data analysis, accuracy ensures that the information being used is reliable and represents the actual state of affairs. By striving for accuracy, we can avoid making decisions based on incorrect or misleading data.

Precision, on the other hand, focuses on the consistency and reproducibility of measurements. In data analysis, precision allows us to determine how closely individual measurements agree with each other. Having precise data means that we can rely on it for making consistent and reliable decisions.

By understanding the difference between accuracy and precision, we can avoid common pitfalls in decision-making processes. Relying solely on precise but inaccurate data may lead to misguided conclusions or actions. Similarly, accurate but imprecise data might not provide the necessary level of consistency required for confident decision-making.

Consider a scenario where a company is analyzing sales figures from different regions to identify potential growth opportunities. Accuracy ensures that the sales figures accurately reflect the actual revenue generated in each region. Precision guarantees that these figures are consistently measured over time and across regions.

Without accuracy, decisions might be based on inaccurate revenue projections or misguided assumptions about certain markets’ performance. Without precision, decision-makers may struggle with inconsistent sales figures that make it difficult to identify trends or patterns accurately.

Knowing the difference between accuracy and precision empowers decision-makers to critically evaluate data sources and measurement methods before drawing conclusions. It encourages them to question whether the information they have is both accurate and precise enough for their specific needs.

In conclusion, accuracy and precision are vital when it comes to making data-driven decisions. By recognizing the distinction between the two, decision-makers can ensure that their choices are based on valid information rather than guesswork or assumptions. This understanding helps build a solid foundation for successful outcomes and enables individuals and organizations to navigate the complexities of our data-rich world with confidence.

Precision instruments are able to measure very small changes in data points, whereas accurate instruments may miss these subtle variations without proper calibration and maintenance procedures in place.

The Power of Precision: Unveiling Subtle Changes

In the world of measurements and data analysis, precision plays a vital role in uncovering the finest details. Precision instruments possess the remarkable ability to detect even the tiniest changes in data points, offering insights that accurate instruments may overlook without proper calibration and maintenance procedures.

When it comes to measuring small variations or subtle shifts, precision is key. These minute changes can hold significant meaning in various fields, such as scientific research, engineering, and quality control. Whether it’s tracking temperature fluctuations in a controlled environment or monitoring chemical reactions at a molecular level, precision instruments excel at capturing these delicate nuances.

Accurate instruments provide measurements that closely align with the true value or target. They ensure that readings are reliable and free from systematic errors. However, accuracy alone does not guarantee the ability to detect small changes. This is where precision steps in as a valuable companion.

Precision instruments are designed to minimize random errors and maximize consistency within repeated measurements. Through meticulous calibration and maintenance procedures, they are fine-tuned to capture even the most minuscule variations in data points. This level of precision enables researchers, scientists, and engineers to delve deeper into their respective fields and unravel hidden patterns or trends.

Consider an experiment where researchers are studying the effects of temperature on a chemical reaction. An accurate thermometer may provide readings within an acceptable range but could miss subtle temperature fluctuations occurring over short time intervals. A precise thermometer, on the other hand, calibrated with utmost care, can capture these minute changes accurately.

In manufacturing processes or quality control procedures, precision becomes paramount for ensuring consistent product quality. Even slight deviations from desired specifications can have significant consequences. By employing highly precise instruments and adhering to rigorous calibration protocols, manufacturers can identify even the smallest variations in product dimensions or characteristics.

Maintenance procedures also play a crucial role in maintaining precision over time. Regular recalibration and verification of instrument performance help ensure that measurements remain accurate and sensitive to subtle changes. By investing in proper maintenance practices, organizations can continue to rely on the precision of their instruments, safeguarding the integrity of their data and decision-making processes.

In conclusion, precision instruments possess the remarkable ability to detect and measure even the most delicate changes in data points. While accuracy provides a solid foundation, precision unveils the intricate details that lie within. By harnessing the power of precision through proper calibration and maintenance procedures, researchers, scientists, engineers, and professionals across various domains can unlock new insights and make informed decisions based on a deeper understanding of their data.

Accuracy is important for providing meaningful results, while precision is important for ensuring consistent performance over time from a given device or system of measurement equipment.

The Distinction between Accuracy and Precision: Importance in Measurement

When it comes to measurements and data analysis, accuracy and precision are two key factors that determine the reliability and usefulness of the results. Understanding their difference is crucial for obtaining meaningful information and ensuring consistent performance from measurement devices or systems.

Accuracy plays a fundamental role in providing meaningful results. It refers to how close a measured value is to the true or target value. In scientific experiments, accurate measurements are vital for drawing valid conclusions and making informed decisions. For instance, in medical research, accurate measurements of drug dosages can determine the effectiveness of treatments. In engineering projects, accurate measurements ensure that structures are built to precise specifications.

On the other hand, precision is essential for ensuring consistent performance over time from a given device or system of measurement equipment. Precision refers to the level of consistency or reproducibility in repeated measurements. It reflects how closely individual measurements agree with each other. High precision indicates that the device or system consistently produces similar results under similar conditions.

Consider a scenario where accuracy is high but precision is low. This means that while the measured values may be close to the true value on average, there is significant variation between individual measurements. Such inconsistency can lead to unreliable conclusions or decisions based on data that fluctuates widely.

Conversely, if precision is high but accuracy is low, this indicates that the measured values are consistently clustered together but significantly deviate from the true value. While such precision may offer consistency over time, it leads to biased results that can misguide decision-making processes.

To obtain reliable and meaningful results, both accuracy and precision need attention. Achieving high levels of both requires careful calibration of instruments, consideration of systematic errors, and accounting for uncertainties in measurements.

In summary, accuracy ensures that measurements reflect reality by closely aligning with the true value being measured. Precision guarantees consistency over time by minimizing variations between repeated measurements taken under similar conditions.

Understanding the distinction between accuracy and precision empowers researchers, engineers, and professionals to make informed decisions based on reliable data. By striving for both accuracy and precision in measurement processes, we can ensure that our results are not only meaningful but also consistently reliable over time.

Accuracy and precision are both key components of quality assurance processes, helping to ensure that products meet customer requirements and industry standards

Accuracy and precision are both key components of quality assurance processes, helping to ensure that products meet customer requirements and industry standards. Let’s delve into how the distinction between accuracy and precision contributes to maintaining high-quality standards.

Accuracy plays a vital role in quality assurance by ensuring that products or services meet the desired specifications or targets. It involves measuring and verifying the conformity of a product or process to predetermined standards. Accurate measurements enable businesses to identify any deviations from the desired outcome, allowing them to make necessary adjustments and improvements. By consistently achieving accurate results, companies can enhance customer satisfaction, build trust, and uphold their reputation for delivering reliable products.

Precision, on the other hand, ensures consistency and repeatability in production processes. Precise measurements allow manufacturers to minimize variations in product attributes, resulting in uniformity and reliability. This is particularly crucial in industries where even slight deviations can have significant consequences, such as aerospace engineering or pharmaceutical manufacturing. By maintaining precision throughout production cycles, businesses can reduce waste, improve efficiency, and deliver consistent high-quality products to their customers.

The combination of accuracy and precision enables businesses to meet customer requirements with confidence. When products are accurately measured against predefined standards, customers can be assured that they will receive exactly what they expect. Additionally, precise manufacturing processes ensure that each product meets the same stringent quality criteria, eliminating inconsistencies between units.

Moreover, accuracy and precision contribute to regulatory compliance in industries with strict standards and regulations. By adhering to accurate measurement practices and maintaining precise manufacturing processes, businesses demonstrate their commitment to meeting industry requirements. This not only helps avoid penalties but also enhances credibility with regulatory bodies.

In summary, accuracy and precision are invaluable assets within quality assurance processes. Their distinction allows businesses to measure conformity accurately against predefined standards while ensuring consistency across production cycles. By prioritizing accuracy and precision throughout their operations, companies can deliver high-quality products that meet customer expectations while complying with industry regulations. Ultimately, this commitment to quality assurance fosters customer satisfaction, builds trust, and strengthens the overall reputation of the business.

Accuracy and precision can be difficult to measure, making it difficult to ensure quality control.

The Conundrum of Accuracy and Precision: Challenges in Quality Control

Accuracy and precision are essential factors in quality control across various industries. However, measuring these parameters can often be a challenging task, leading to difficulties in ensuring consistent and reliable outcomes. The subtle distinction between accuracy and precision adds complexity to the process, requiring careful consideration and attention to detail.

One of the primary challenges lies in accurately assessing the true value or target against which measurements are compared. In many cases, there may not be an absolute reference point available for comparison. This lack of a definitive standard makes it difficult to determine the accuracy of measurements accurately. Without a reliable benchmark, it becomes challenging to gauge how close or far off our measurements actually are from the desired outcome.

Moreover, measuring precision can also be a complex endeavor. Precision relies on obtaining consistent and reproducible results through repeated measurements. However, various factors, such as environmental conditions, human error, or equipment limitations, can introduce variability into the measurements. This inherent variability makes it difficult to ascertain the true level of precision achieved.

Another aspect that adds to the challenge is the trade-off between accuracy and precision. Often, improving one parameter comes at the expense of the other. For instance, increasing precision may require more time-consuming measurement techniques or sophisticated equipment that may introduce additional sources of error. Balancing these trade-offs becomes crucial for achieving optimal quality control.

Additionally, ensuring accuracy and precision throughout large-scale operations or complex systems can be demanding. Variations across different measurement points or stages of production can further complicate quality control efforts. Maintaining consistency across multiple processes or locations requires meticulous planning, calibration procedures, and continuous monitoring.

To address these challenges effectively, organizations must invest in robust quality control measures. This includes implementing rigorous calibration protocols for instruments used in measurements and adopting statistical techniques to assess accuracy and precision levels. Regular training programs for personnel involved in data collection can also help minimize human errors.

Furthermore, developing and adhering to standardized procedures and protocols can enhance consistency and comparability in measurements. By establishing clear guidelines for accuracy and precision evaluations, organizations can streamline quality control processes and minimize discrepancies.

While the conundrum of accuracy and precision in quality control poses challenges, it also underscores the importance of continuous improvement. Striving for higher levels of accuracy and precision encourages organizations to invest in advanced technologies, refine measurement techniques, and adopt best practices. Over time, these efforts can lead to more reliable outcomes, improved product quality, and enhanced customer satisfaction.

In conclusion, the difficulty in measuring accuracy and precision presents a notable challenge in quality control. However, by recognizing these hurdles and implementing effective strategies to overcome them, organizations can navigate this conundrum successfully. By prioritizing accurate measurements and consistent results, businesses can ensure that their products or services meet the highest standards of quality control.

Lack of accuracy and precision can lead to data misinterpretation or incorrect decisions being made.

The Consequence of Inadequate Accuracy and Precision: Misinterpretation and Incorrect Decisions

In the realms of science, engineering, and countless other fields, accuracy and precision play pivotal roles in ensuring reliable data analysis and informed decision-making. However, when accuracy and precision are lacking, the consequences can be significant, leading to misinterpretation of data or even incorrect decisions being made.

When measurements lack accuracy, they fail to represent the true value or target being measured. This can stem from various factors such as instrument calibration issues, systematic errors, or flawed experimental procedures. Inaccurate measurements can introduce biases into data analysis and lead to incorrect conclusions. For example, if a medical test produces inaccurate results for diagnosing a disease, it could potentially lead to misdiagnosis or inappropriate treatment.

Similarly, when precision is insufficient in repeated measurements, it implies a lack of consistency or reproducibility. The presence of random errors or variations between measurements can obscure patterns or trends within the data. This can make it challenging to draw accurate conclusions or identify meaningful relationships between variables. For instance, in environmental monitoring studies where precise measurements are crucial for detecting subtle changes over time, inadequate precision may result in overlooking important shifts in ecosystems.

Misinterpretation of data arising from inadequate accuracy and precision can have far-reaching consequences across various domains. In scientific research, it may lead to flawed theories or unreliable findings that hinder progress within a particular field. In engineering projects, it could result in faulty designs or compromised safety measures due to incorrect calculations based on imprecise data.

Moreover, incorrect decisions made due to inaccurate or imprecise information can have real-world implications. In sectors such as finance and economics, decisions based on flawed data analysis could have severe economic repercussions on individuals and businesses alike. In healthcare settings where accurate diagnoses are essential for effective treatment plans, wrong decisions stemming from inaccurate measurements may jeopardize patient well-being.

To mitigate these risks associated with inadequate accuracy and precision, it is crucial to prioritize the calibration of instruments, minimize systematic errors, and employ rigorous experimental methodologies. Additionally, increasing the number of measurements taken and reducing random errors can enhance precision and improve the reliability of data.

By recognizing the potential consequences of inadequate accuracy and precision, researchers, professionals, and decision-makers can remain vigilant in their pursuit of reliable data analysis. By prioritizing accuracy and precision in measurements, they can ensure that their interpretations are sound, decisions are well-informed, and the impact of their work is both meaningful and beneficial.

Poor accuracy and precision can result in costly mistakes, such as inaccurate inventory counts or incorrect measurements in manufacturing processes.

The Consequences of Poor Accuracy and Precision: Costly Mistakes

In various industries, accuracy and precision are of utmost importance to ensure smooth operations and reliable outcomes. However, when accuracy and precision are compromised, the consequences can be significant, leading to costly mistakes that impact businesses and individuals alike.

One prevalent consequence of poor accuracy and precision is inaccurate inventory counts. Whether it’s a retail store, a warehouse, or a distribution center, having an accurate understanding of available stock is crucial for efficient supply chain management. If inventory counts are not conducted with precision and accuracy, it can result in overstocking or understocking products. Overstocking ties up capital in excess inventory that may not sell quickly enough, leading to financial losses. On the other hand, understocking can result in missed sales opportunities and dissatisfied customers. Both scenarios can have detrimental effects on profitability and customer satisfaction.

In manufacturing processes, the impact of poor accuracy and precision becomes even more pronounced. Measurements play a vital role in ensuring product quality and adherence to specifications. If measurements are inaccurate or imprecise during production, it can lead to faulty products that do not meet required standards. This can result in increased waste, rework costs, customer complaints, recalls, or even legal issues if safety regulations are violated. Moreover, incorrect measurements may also affect the performance or functionality of the final product, potentially damaging brand reputation and customer trust.

Additionally, poor accuracy and precision can have ripple effects throughout an organization’s operations. It can lead to misinterpretation of data or incorrect decision-making based on unreliable information. This can result in misguided strategies or ineffective resource allocation that hampers overall performance.

To mitigate these risks associated with poor accuracy and precision, organizations must prioritize investing in accurate measurement tools and techniques while ensuring proper calibration procedures are followed regularly. Quality control measures should be implemented to detect any deviations from desired standards promptly. Training employees on accurate measurement techniques and the importance of precision can also significantly contribute to reducing errors.

Ultimately, the cost of poor accuracy and precision extends beyond financial losses. It can impact customer satisfaction, brand reputation, and overall business success. By recognizing the significance of accuracy and precision in various processes, organizations can take proactive measures to minimize mistakes and ensure reliable outcomes, thereby safeguarding their bottom line and maintaining a competitive edge in today’s demanding market.

If accuracy and precision are not maintained, the results of any experiment or process may be unreliable and invalidate the results obtained from it.

The Importance of Maintaining Accuracy and Precision in Experiments

Accuracy and precision are vital aspects of any scientific experiment or process. Failure to maintain these qualities can lead to unreliable results, potentially invalidating the entire endeavor. Understanding and upholding accuracy and precision is crucial for ensuring the integrity of scientific research and the validity of its outcomes.

When accuracy is compromised, the measured values deviate from the true or target value. This can occur due to systematic errors, such as faulty equipment or incorrect calibration. Inaccurate measurements introduce a significant bias into the results, rendering them misleading or even useless. Imagine a medical study that incorrectly measures the effectiveness of a new drug due to inaccurate data; this could lead to misguided conclusions and potentially harmful consequences for patients.

Precision, on the other hand, relates to the consistency and reproducibility of measurements. If precision is not maintained, there will be significant variation between repeated measurements. This may result from random errors caused by factors like environmental conditions or human error during data collection. Lack of precision undermines confidence in the reliability of experimental data, making it difficult to draw meaningful conclusions or make informed decisions based on the results.

When both accuracy and precision are compromised simultaneously, it amplifies the unreliability of experimental results even further. In such cases, it becomes challenging to discern whether any observed differences or trends are genuine effects or simply artifacts caused by measurement errors.

Maintaining accuracy and precision requires careful attention to detail throughout an experiment or process. Regular calibration of instruments, adherence to standard operating procedures, controlling environmental variables, and minimizing human biases are all essential practices for ensuring accurate and precise measurements.

It is worth noting that some experiments inherently involve uncertainties due to inherent limitations in measurement techniques or complex systems being studied. However, acknowledging these uncertainties doesn’t diminish the importance of striving for accuracy and precision within those limitations.

By prioritizing accuracy and precision in scientific endeavors, researchers can enhance confidence in their findings while contributing to the overall advancement of knowledge. Reliable and valid results are essential for building upon existing research, making informed decisions, and ultimately improving our understanding of the world around us.

In conclusion, maintaining accuracy and precision is crucial for the integrity and reliability of experimental results. Failing to do so can render the outcomes unreliable and potentially invalidate the efforts invested in an experiment or process. By upholding these qualities, scientists ensure that their work contributes meaningfully to scientific progress and enables evidence-based decision-making.

Hi my loved one! I wish to say that this article is amazing,

nice written and come with almost all important infos.

I’d like to look extra posts like this .

Thank you for your kind words! We’re glad to hear that you found the article amazing and well-written. We appreciate your feedback and will strive to provide more informative posts like this in the future. Stay tuned for more content on various topics, including accuracy and precision.